Drywall Innovations

THE LATEST IN GYPSUM BOARD PRODUCTS AND THE ACCESSORIES/TOOLS THAT ARE AFFILIATED WITH THEM.

A round-up of new drywall products introduced to the market recently. These new products are designed to either cut labor time, improve productivity or help with custom drywall work.

Many new products that are centered around the drywall universe will be featured at this year’s trade events. The following are a selection of new launches that reflect these new changes and offer other interesting features for the drywall contractor.

Gypsum-based Products/Systems

No stranger to offering an extensive line of gypsum sheathing solutions, Georgia-Pacific Gypsum frequently updates its portfolio of gypsum-based products. Most recently, it has introduced its DensElement Barrier System, which consolidates the sheathing installation and water-resistive barrier process by integrating gypsum sheathing, a water-resistive barrier and an air barrier.

This barrier system helps reduce the risk of inconsistent weather-resistive barrier and air barrier (WRB/AB) application in the field by eliminating the need for a separate WRB/AB. This system eliminates a step in the installation process, freeing builders and installers from manually applying a WRB/AB over the sheathing on the jobsite or in the factory. It is compatible with the company’s DensDefy products, including liquid flashing, transition membrane and the recently introduced liquid barrier.

Buildings require effective WRB/ABs but as the labor pool is shrinking, the construction schedules are getting tighter. In response to industry and construction challenges, the barrier system was developed to give builders an integrated sheathing that offers them a high-performance, efficient WRB/AB from a trusted manufacturer.

Interested parties can view the products at the upcoming GMS Expo and INTEX Expo this fall. For more information, visit buildgp.com/gypsum.

Prefab Drywall Soffit Framing System

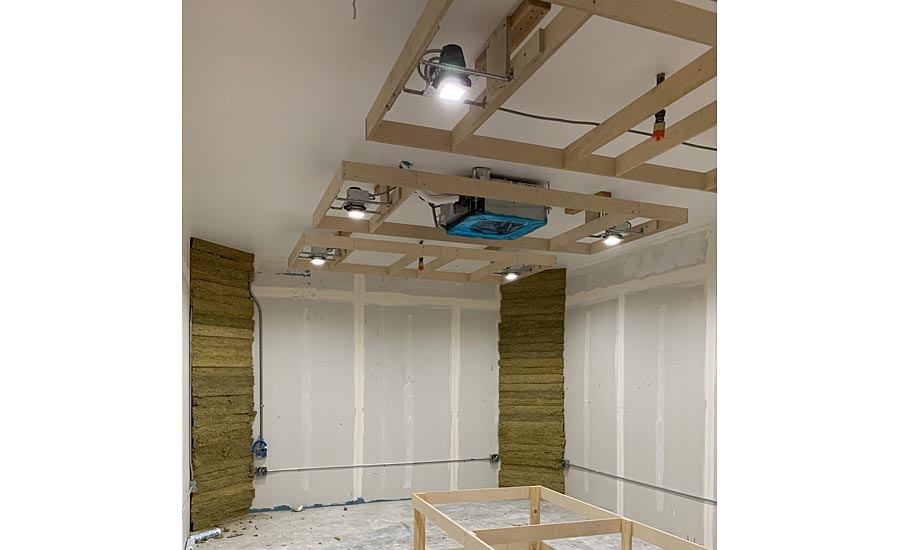

Armstrong Ceiling Solution’s SimpleSoffit is an all-new prefabricated drywall soffit framing system factory notched to project specifications; main beams quickly click into shape right out of the box and install rapidly saving time, material and labor on the jobsite. Soffits are a part of every ceiling installation and require extra man-hours and onsite fabrication time. It’s a faster, easier way to build soffits without jigs and prefabrication time. The system is meant for:

- Estimators

- Project Managers

- Foreman/Installers

“Armstrong provides easy quoting and quick turnaround on drawings making it fast and easy to order and implement to a project’s specific soffit design,” says Channel Sales & Development Manager, Brett Sareyka. “[The product] is a fast, easy way to build soffits right out of the box—no jigs, no prefabrication time, no training required. Onsite installation is as easy as bend, click and go.”

The drywall framing items are available for projects in which the exact soffit dimensions are not known and a quick delivery is needed. Its custom main beams with notch locations are based on the project soffit plan. Its pre-engineered drywall grid main beam, specifically designed for soffit application, speeds soffit installation two times faster than stud and track. The factory rout locations are determined based on project plan; allows cross tee placement and eliminates material waste with fixed rout locations. It easily integrates with drywall grid, AcoustiBuilt ceilings, transitions, perimeter solutions and other Armstrong ceiling systems.

For more information, visit armstrongceilings.com/simplesoffit.

Flexible Bead for Drywall

ClarkDietrich’s X-Crack’s rigid design, hinged backbone, and flexible tab design will straighten all uneven framing members. This pre-straightening of the sub-structure will eliminate the need of all pre-filling due to irregularities of the framing members. It makes easy work of intricate ceiling applications that have no backing and eliminates cracking.

There are several areas which are prone to cracking and benefit from the use of X-Crack: vaulted ceilings, butterfly vaults, areas where framing members are out of alignment, ceiling areas where the drywall is not properly supported and/or where movement may occur—causes for this movement may be due to lumber shrinkage, snow or wind loads, expansive soil, and/or truss uplift.

“Though it is best practice to install X-Crack during the initial framing installation, the product can also be used when renovating the conditions above after they have cracked,” says Jake Reece, product manager. “This means that residential new construction and remodeling contractors benefit from using X-Crack.”

The product is simple to install and use—the “magic,” is in the technology, not in a complicated installation technique. Simply screw X-Crack to the framing members and then attach the drywall board to the flanges of the product.

The hinged backbone of X-Crack allows it to conform to any angle for inside, outside, and off-angle installations. It has a rigid structure which supports the weight of the materials and ensures a proper attachment to the framing, while the flexible tabs allow for the independent movement that prevents cracking in areas with those crucial finishing details.

“Once a customer has used X-Crack and has seen that it works as advertised, they use it every time they have an application for it,” says Reece. “It makes the job easier, and it is cheap insurance against call backs for an extremely common cracking issue in key visual areas.”

The product is distributed by ClarkDietrich as well as its nationwide network of distribution partners. Currently, X-Crack is available in the U.S., Canada, all of Europe, New Zealand, and Australia.

The company will present the complete line of framing and finishing products at INTEX Expo, held this year in New Orleans, in October.

For more information, visit clarkdietrich.com/products/strait-flex-x-crack.

Multi-layered Gypsum Panel

PABCO Gypsum’s QuietRock 545 is a multi-layer gypsum containing composite panel that is engineered to provide maximum sound attenuation (60-80 STC) across a broad frequency range. It provides the highest sound isolation performance on the market at low frequencies (50 HZ to 100Hz) which is often difficult to achieve. The recent development with the board is the addition of UL fire-resistance rated assemblies. It has passed a 2-hour wall assembly fire test (UL W466) with one panel on either side of the wall and a 1-hour floor/ceiling assembly (UL M552), proving that it is truly a super panel.

The gypsum panel was originally introduced into the market as the ultimate home theater panels focusing on not only high STC results but more precisely on low frequency noise and vibration isolation on wood frame construction. Over the years with added testing, QuietRock became popular in commercial construction as well, in theaters, nightclubs, studios, hotels, churches, and for mechanical room isolation. It is ideal for high-end home theaters, commercial theaters, professional studios, music rooms, and other projects where low-frequency mitigation is critical.

The panel installs and finished just like drywall with a few exceptions:

- Panels are heavy—nearly 200 pounds for a 4-feet by 8-feet sheet; it is more weight than one person can handle during installation.

- Panels contain a thin layer of galvanized steel; therefore, they must be cut with a saw. See the manufacturer’s installation instructions for details.

Its key features include:

- Highest performing sound reducing gypsum containing composite panel available

- Delivers superior sound reduction for both high and low frequencies

- Exceptional low frequency performance

- Ideal for high-end home theaters, studios, commercial theaters, and mechanical rooms and other situations were low frequency noise and vibration require isolation

- Continues to reduce noise even when fixtures are installed

- Lab tested and proven to outperform other sound attenuation methods, including multi-layered gypsum panels, resilient channel and soundboard

- High STC ratings, tested up to STC 80

The product is distributed at:

- ABC/L&W Supply

- Beacon/Allied

- Foundation Building Materials

- GMS/GTS

- Pacific Coast Supply

- AD Supply

- US-LBM

- KAMCO

- TimberMart (Canada)

- Torbsa (Canada)

The product is available in the U.S. and Canada. It can be viewed at this year’s INTEX Expo. For more information, visit pabcogypsum.com.

Dust Extractor

Engineered to meet OSHA’s silica dust requirements for construction applications, the iQ426HEPA captures over 99 percent of dust before it even reaches the filter via its 4-stage cyclonic filtration system. This cyclonic process gives the iQ426HEPA its powerful 190 CFM of suction power, making it the most efficient dust extractor in its class. Includes iQ steel Cart, 14-foot hose, 10-gallon dust tub, water-lift up to 100 inches and multiple accessories.

“To solve our own dust problems, we started to build our own dust solution tools,” says Marketing Director Sarah Williams. “However, we realized these problems were affecting all contractors. So, we started iQ … to bring dust solutions to all contractors.”

The iQ426HEPA was developed to increase the efficiency for the drywall installer by increasing the CFM and eliminating the need to continuously clean the filter. Its cyclonic technology and patented filter cover design, allows the contractor to collect more dust in a faster amount of time.

iQ Power Tools strives to create quality smart tools that keep the contractor efficient and safe. They are passionate about mitigating the amount of silica on the job site and educating the construction industry about silica awareness.

What makes this vacuum dust collection system work is the two stages of cyclonic filtration because this means that less than 1 percent of the dust ever reaches the filter. With a clean filter, vacuum suction stays strong and operating at its optimum performance level. The cyclonic filtration process and a clean filter is what gives the product its powerful 190 CFM of suction power, making it the most efficient dust extractor in its class.

To service the tool, users need to spin the filter a few times at the end of the day. The company recommends changing the Durabond and HEPA filters at least once a year.

For more information, visit iqpowertools.com.

Orbital Drywall Sander

Festool USA’s new Planex LHS 2 225 Drywall Sander advances the company’s previous best-in-class generations of drywall sanders with innovative features that enhance efficiency and results on the jobsite. Featuring a new LED light ring that ensures detailed visibility of the sanding path, the sander enables the user to see any unevenness on the surface during sanding. Because this on-board illumination immediately highlights surface irregularities, it also reduces the time needed to fix any problems, helping end-users achieve a better finished product in less time. The product uses a random orbit sanding motion to eliminate grooves and to ensure a flawless finish.

The adjustable suction power on the lightweight tool, which keeps the tool snug with the work surface—helps to reduce the workload placed on the user’s arms and back. The tool connects to the CT 36 E AC dust extractor to create a nearly dust-free sanding solution. To also combat dust, Festool has unveiled a new version of the high-quality Granat abrasive. A new hole pattern allows for even better dust extraction when used with any of the Festool drywall sanders.

The tool is engineered for any situation. With the addition of the guide extension accessory, the 47-inch tool can reach up to 65 inches. This machine is equipped for both high ceilings and tight spaces. Its ergonomic T-handle means the machine is easy to maneuver for long periods. Once the job is complete, the product and its accessories conveniently travel in the new Festool SYS3 XXL Systainer.

Backed by the company’s three-year, all-inclusive warranty, the product is built for the toughest demands. For more information, please visit festoolusa.com.

Fire-rated Drywall Accessory

CEMCO’s Fire-Rated Drywall Accessory is a single-step drywall product that is paintable, takes the place of fire sealant, easy to install, easy to inspect, and remains flexible for the life of the assembly.

The traditional method of fire sealants can be difficult to properly install. Over time, both fire sealants and sound sealant will harden and lose the ability to maintain flexibility and not all sound/fire sealants are paintable so finishing options can be limited.

Drywall contractors will benefit from this because the line offers labor savings and vastly limits installer errors. Architects will take note as well because the Fire Rated Drywall Accessories offer a sustainable life warranty and offer many other benefits for LEED and LEAN building projects.

Non-rated drywall accessories have been installed for years so the learning curve is minimal.

There are several offerings within this product line:

- 093X-V (Fire-Rated Control Joint)

- Fire Bead (Fire-Rated Deflection Bead)

- Fire Gasket (Firestop for Building Joints)

- Sound Gasket (Sound Stop for Building Joints)

- HOTROD XL (Fire Rated Deflection Bead)

All fire-rated products are tested through UL and have received certification per UL-2079 5th addition. In addition, all products have also been 3rd party sound tested through ASTM E90.

Its key features include:

- Esthetics (all products are paintable and are incorporated into the wall assembly so that do not standout)

- Ease of use (all products have very basic installation requirements)

- Free of long-term maintenance (products come with a sustainable life warranty and once installed no maintenance is required)

- High deflection/dynamic movement (offers 3-4 times the amount of movement that traditional firestopping offers)

- High STC Values (third party sound tests proved that the products would match or exceed STC numbers of sound sealant)

“This product line has been a game changer. In a short amount of time several projects have switched from traditional methods to use this line of fire rated drywall accessories,” says CEMCO’s R&D Manager Don Pilz. “Project analysis from contractors have proven that there is both a time and labor savings from using the product line.”

The line is distributed nationwide and currently sold also in Canada and the United Kingdom. Visit CEMCO at this year’s INTEX Expo or visit cemcosteel.com.

GreenGuard Certified Tile Backer Board

Expanding on its GlasRoc portfolio of wall and ceiling products, CertainTeed Gypsum presents GlasRoc Tile Backer and GlasRoc Tile Backer Type X. These products were introduced this May.

To provide an easy-to-use product that meets increasingly stringent building codes and industry standards. GlasRoc Tile Backer is the result of CertainTeed’s commitment to sustainability—it is GreenGuard Gold Certified and carries a Health Product Declaration, which provides material transparency and helps projects achieve LEED and other Green Building rating goals.

The target audience is for North American installers, contractors and subcontractors working within the residential and commercial building markets.

According to Vice President, Gypsum Marketing Najwa Khoury, there is no learning curve and the backer cuts and snaps like standard gypsum panels. It weighs up to 30 percent less than standard cement backer boards, making it much easier to cut, handle and install.

The gypsum panels feature a specially formulated moisture-resistant core with engineered fiberglass facers, making them ideal for use behind tiles in interior rooms frequently subjected to moisture and high humidity, such as tub and shower surrounds, bathrooms, kitchens, laundry rooms, utility rooms and other spaces. In addition, Type X is UL and ULC certified and may be used in UL and ULC fire resistance-rated assemblies.

The line gives the installer added flexibility because of the product’s wide range of acceptable thinsets and adhesives. Depending on the application, the backer provides excellent adhesion with unmodified thinset, latex/polymer modified thinset, and mastic adhesives.

Available in 1/2-inch thick, 4-foot by 8-foot sheets and in 5/8-inch thick sheets, GlasRoc Tile Backer is ideal for walls, ceilings and countertops when installing ceramic tiles, and as a wall backing for laminate-faced panels and fiberglass shower units and tubs, providing moisture, fire and sound resistance.

The line is now available in the U.S. and Canada, and should see an appearance at selected trade shows this year. For more information, visit certainteed.com/drywall.

For more articles like this, and to enjoy our eMagazine on an engaging, user-friendly platform, subscribe here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!