Code Changes for WRBs/Rainscreens for Plaster

Managing moisture in the wall cavity—particularly incorporating methods for draining bulk water—continues to be a growing concern for the industry. Requiring or specifying a drainage space between the water-resistive barrier and the exterior wall covering has quickly become part of this moisture management strategy. Now, recent changes to the International Building Code and International Residential Code are bringing new drainage requirements to a larger portion of the country, meaning builders and contractors may need to rethink how they approach building envelope design going forward.

Understanding Water-Resistive Barriers

Water-resistive barriers are an intervening layer installed behind exterior wall coverings to resist moisture and provide protection to underlying components. Common types of WRB materials include roll goods, such as flexible sheets (ASTM E 2556 Type 1 or 2) and asphalt-saturated organic felt (ASTM D 226 Type 1 No. 15 felt), specialized sheathings comprised of foam plastic, wood or gypsum-based products, fluid-, liquid-, or roller-applied materials and self-adhered membranes.

Typically, the type of WRB is selected by the design professional based on considerations such as permeability, compatibility with the exterior wall covering and substrate, local environment, performance requirements, design preference, cost and building code requirements. Increasingly, WRB selection is driven by the need to incorporate drainage into the wall. Common designed drainage methods include traditional, unventilated drainage cavities or spaces and rainscreen systems, which consist of a drainage cavity and capillary break, plus ventilation to promote drying.

Drainage spaces are commonly created by open design drainage mats which typically range in depth or thickness from 6 millimeters (1/4-inch) to 10 millimeters (3/8-inch). Building code requirements for cement plaster applied over wood-based sheathing often require a two-layer water-resistive barrier or equivalent, such as a WRB and an intervening material or spacer, like a drainage mat or a rainscreen system, which provides a ventilated air space.

Drainage Considerations for Exterior Plaster

Water-resistive barrier requirements for plaster differ from that of many other exterior wall coverings. This is because the cementitious material will get wet and dry countless times throughout its lifetime of service, creating a unique environment in which bulk water drainage is particularly important. Below summarizes important items and considerations specific to stucco applications:

- The water resistive barrier should be integrated with flashings, other building elements, lath (such as metal lath) and accessories, including weep screeds, joints, casing beads, etc. Failure to do so could result in water infiltration at openings, which are hard to trace to the source.

- Fluid-applied and similar water-resistive barriers, which are sometimes applied to concrete or masonry, generally require a mechanical bond or key, such as metal lath, for adhesion of the stucco.

- Water-resistive barrier requirements and strategies may include designed drainage spaces that incorporate drainage mats or other means to create a rainscreen or unventilated drainage cavity.

- Penetrations through the water-resistive barrier should be minimized by utilizing the prescribed number of fasteners only necessary for lathing and accessories.

New Code Verbiage That’s Driving Change

2021 International Building Code and 2021 International Residential Code Changes

Below is a summary of IBC and IRC provisions for water-resistive barriers used with cement plaster. The provisions can differ based on the building code, water-resistive barrier material, type of substrate or backing and climate zone.

Water-resistive barrier requirements shown in italics are impacted by the Climate Zone or geographical location of the project. Figure 1 is the U.S. Climate Zone map from the 2021 International Energy Conservation Code, which, based on geography, defines climates as “Moist, Dry or Marine.”

Each zone is subdivided numerically, as shown in Figure 1. More detailed Climate Zone information is available by state, county or territory in Table C301.1 of the 2021 International Energy Conservation Code. The following steps determine the water-resistive barrier requirements for projects impacted by Climate Zone:

- Find the geographic project location based on Figure 1 or 2021 IECC Table C 301.1.

- Locate the relevant Climate Zone.

- Determine the water-resistive barrier based on the applicable building code, section, and substrate or backing material.

2021 International Building Code

Substrate materials and relevant code sections:

-

Concrete or Masonry Walls

- 1402.2 Exception 1—A water-resistive barrier/envelope is not required, provided walls are designed per IBC chapters 19 and 21, respectively.

-

Wood-Based Sheathing Walls

-

2510.6.1—Water-resistive barrier options - dry climate zones

- 1. Two layers of 10-minute Grade D paper or water resistance equal to or greater than two layers of water-resistive barrier complying with ASTM E 2556 Type 1. For two-layer applications, each individual layer shall be installed independently. The water-resistive barrier and any flashings shall direct water to drain between the layers.

- 2. The water-resistive barrier shall be 60-minute Grade D paper or a water resistance greater than or equal to one layer of water-resistive barrier complying with ASTM E 2556 Type 2. The water-resistive barrier shall be separated by an intervening layer or drainage space.

-

2510.6.2—Water-resistive barrier options—moist or marine climate zones

- 1. Comply with option 1 or 2 in 2510.6.1 with a space or drainage material not less than 3/16-inch in depth on the exterior side of the water-resistive barrier.

- 2. Comply with option 2 in 2510.6.1 and drainage on the exterior side of the water-resistive barrier shall have a minimum drainage efficiency of 90 percent in accordance with ASTM E 2273 or Annex A2 of ASTM E 2925.

-

2021 International Residential Code

Substrate materials and relevant code sections:

-

Concrete or Masonry

- 703.1.1 Exception 1—A water-resistive barrier/envelope is not required, provided walls are designed per IRC chapters 703.4 and 703.8, respectively.

-

Wood-Based Sheathing

-

703.7.3.1—Water-resistive barrier options - dry climate zones

- 1. Two layers of 10-minute Grade D paper or water resistance equal to or greater than two layers of water-resistive barrier complying with ASTM E 2556 Type 1. For two-layer applications, each individual layer shall be installed independently. The water-resistive barrier and any flashings shall direct water to drain between the layers.

- 2. 60-minute Grade D paper or water resistance equal to or greater than one layer of water-resistive barrier complying with ASTM E 2556 Type 2. The water-resistive barrier shall be separated from the stucco by a layer of foam plastic insulating sheathing or other non-water absorbing layer or drainage space.

-

703.7.3.2—Water-resistive barrier options—moist or marine climate zones

- 1. Comply with 703.7.3.1 Item 1 and a space or drainage material not less than 3/16-inch in depth added on the exterior side of the water-resistive barrier.

- 2. Comply with 703.7.3.1 Item 2 and drainage on the exterior of the water-resistive barrier with an efficiency of not less than 90 percent in accordance with ASTM E 2273 or Annex A2 of ASTM E 2925.

-

Drainage Mat Rainscreens for Exterior Wall Covering

To achieve these new drainage gap requirements, builders and contractors have several options. Furring strips and Z-furring are viable options, as well as simple rainscreen mats. Many rainscreen products feature a 95 percent open design, which provides an effective spacer for unventilated drainage cavities and other designs which incorporate a cavity. They also provide a capillary break and enable ventilation.

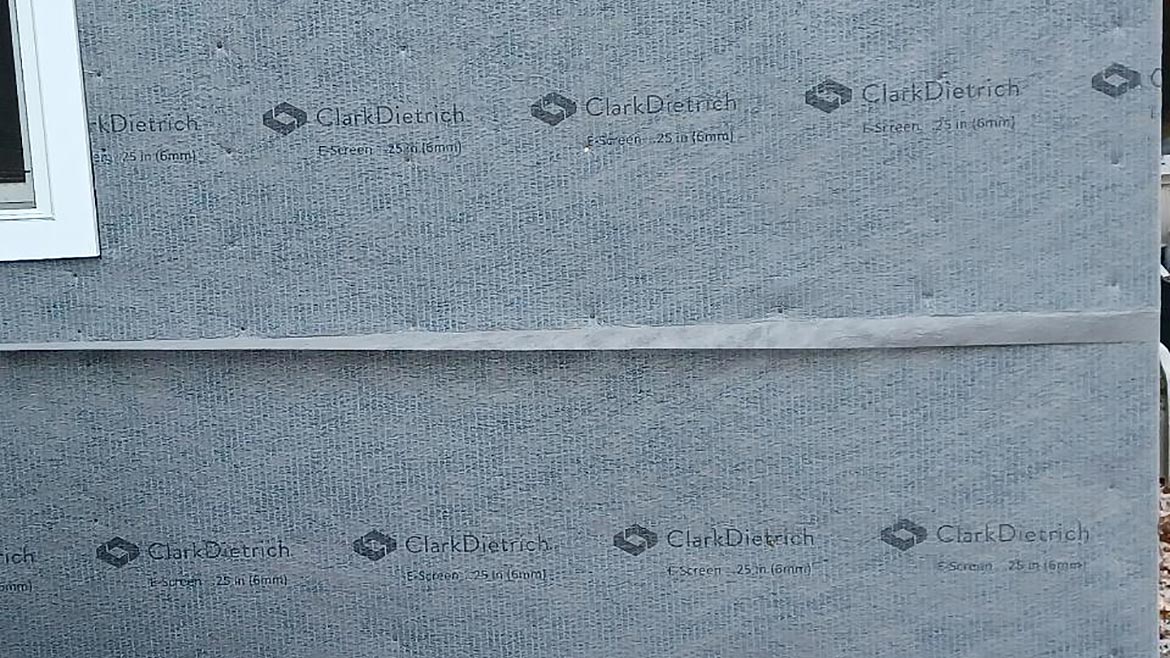

Rainscreen mats are suitable for use with stucco, adhered manufactured stone veneer, brick and other exterior wall coverings. Many are durable, polymer-based entangled mesh material that are corrosion-resistant, rust-proof and mildew-resistant. The two-ply design incorporates a backer fabric, which alleviates blockage of the drainage space during stucco or mortar applications. ClarkDietrich E-Screen (see photo) complies with these simple criteria to achieve a code-compliant drainage gap. Be aware any metal lath applied over the drainage mat must still be fully covered with plaster scratch-coat or mortar to embed the lath. Self-furring lath is required to achieve this embedment.

Expect local code jurisdictions to begin adopting this new IBC/IRC code verbiage in the coming years.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!