New Innovations

A selection of some of the new products showcased at industry trade shows this year.

Each year, it’s exciting to see all the new products announced at various industry trade shows. In keeping with our tradition of reporting on drywall—and other innovations, here is a handful of new or enhanced products released specifically for the wall and ceiling market. All of these innovations are aimed to help wall and ceiling contractors with productivity and ergonomics, among other benefits.

W&C spoke with several companies to see what’s new in the field and have them tell us in their own words about their new products.

Premium Ceiling Systems

Armstrong World Industries

Armstrong prides itself as a regular participant in the industry’s largest trade shows and featured some of its latest productivity and construction efficiency solutions in ceiling framing and installation. The company is also present to sponsor, support and participate in two of our industry associations’ conferences and events—CISCA and AWCI.

According to its marketing communications manager, Jeff Wolfe, the company finds the largest benefit of attending the show is the continuing influence of technology and even AI involved in many areas of construction.

This year, the company introduced and featured several new products:

- Lyra Wood-Look Ceiling Planks Integrated

- Axiom Trim and Light Coves (not new but part of their integration efficiency/productivity story)

- SimpleSoffit Framing System (not new but part of their integration efficiency/productivity story)

- FrameAll Drywall Grid (not new but part of their integration efficiency/productivity story)

- Axiom Transitions (curved extruded aluminum; not new but part of their integration efficiency/productivity story)

- DynaMax / DynaMax Plus Structural Grid

- ProjectWorks Pre-Construction Service (not new but part of their construction efficiency story)

For more information, visit Armstrong.com.

Ceiling Tile Workstation

Arrow Fastener/Grabber Construction Products

The RevealCut Ceiling Tile Workstation is a ceiling tile cutter designed for ceiling installation professionals to cut factory-quality ceiling tile profile edges with speed and precision, along with the workstation’s utility blades.

The product is available in two sizes: one for 2-foot tiles and a larger version for up to 4-foot tiles, using new blade technology designed specifically for cutting through fibrous ceiling tiles, which as a result, can create factory grade cuts in less than 30 seconds. These proprietary cutting blades can cut up to 200 times before needing a replacement blade, leading to faster and more efficient installs, especially when compared to the typical five cuts with standard utility blades.

“After a successful introduction launch period, and entry in the walls and ceiling industry, RevealCut is poised to transform the way ceiling tile installers, general contractors, and facilities and maintenance professionals work for the better, not only resulting in labor savings and less wasted materials, but also improving overall jobsite safety by implementing much safer cutting procedures,” says Roberto Izaguirre, vice president of marketing and sales, Arrow Fastener.

Based off the success of its popular booth at such shows as BUILD'23, Grabber Construction Products picked up the product for distribution. “We are thrilled to partner with Arrow Fastener and lead the charge on the distribution of this game-changing workstation,” says Ryan Gross, director of product category management, Grabber Construction Products. “As a company, we pride ourselves in the manufacturing and distribution of innovative tools that advance contractor productivity, and we see Arrow RevealCut disrupting the commercial construction industry by providing ceiling tile professionals with a tool that will change the category forever.”

For more information, visit grabberpro.com.

Drywall Milling Machine

Automated Precision Equipment (APE)

The company’s Automated Cutting/Milling Machine is designed for drywall (and to another extent, plywood). It combines CNC technology with user-friendly design to increase productivity, safety and cost efficiency.

According to CEO Kurt Norgaard, the company saw the potential of the “beadless” machines years ago and developed a user-friendly, industrial CNC three-tool headed CNC drywall, plywood cutting/milling machine to do all the beadless things and much more. Once the company started working with prefabrication firms, it realized that the CNC machine was only one piece of a commercial system, so the company modified the machine, built a lift and glue table, and sourced a great dust collection/gluing system to have a full-engineered system to leverage the full capabilities of the machine.

“Our engineered solution helps our customers optimize the way they work with proven cutting-edge, easy-to-use, automated tools that include fast loading and flipping of material, standard drywall shapes at the touch of a button, automated multi-directional saw cutting and pop-up roller balls for easy material movement,” Norgaard says.

The main features of the product include:

Maximizing Production Volumes: With APE’s machinery, companies have quadrupled their production volumes, streamlining operations and increasing throughput;

Making it a One-Person Job: Transform your operation from a two-person job to a single-operator process, enhancing efficiency and dramatically reducing labor costs;

Saving Time and Materials: Cut down on both labor and material costs by getting the most out of each hour and each sheet of material, and;

Cut through the Complications: Designed with simplicity in mind, the touch-screen controls and intuitive interfaces mean your operators can be up and running after just a few hours of training.

The company plans to target subcontractors that are currently or want to move into automation and prefabrication, in almost any manner. The company has systems set up both for prefabrication and innovation centers, along with on-site installations. All that is needed is a dry, secure space and electricity. Automated Precision Equipment will guide the planning and setup that fits the needs of the job.

The company attended this year’s BUILD24 to see it and, of course, to check out the evolution of the industry.

Norgaard learned a lot from attending this year’s show. “Change is happening. More than ever, the pace of technology change is increasing, adapting to the latest technologies,” he says. “Firms are no longer afraid of such labels as CNC and automation.”

Some contractors have weighed in on their thoughts of the CNC machine.

Jake Wolfer, vice president of prefab at Valley Interior Systems, says, “The user-friendly software means we can take anyone out of the shop and, within five to 10 minutes, have them up and running for the day and know they will be running successfully all day.”

According to T.J. Wies Contracting, who was very active at this year’s BUILD24, “APE’s machine turned a two-man operation into a one-person operation and then quadrupled the actual output of that one person.”

For more information, see the link for an introductory video to the machine.

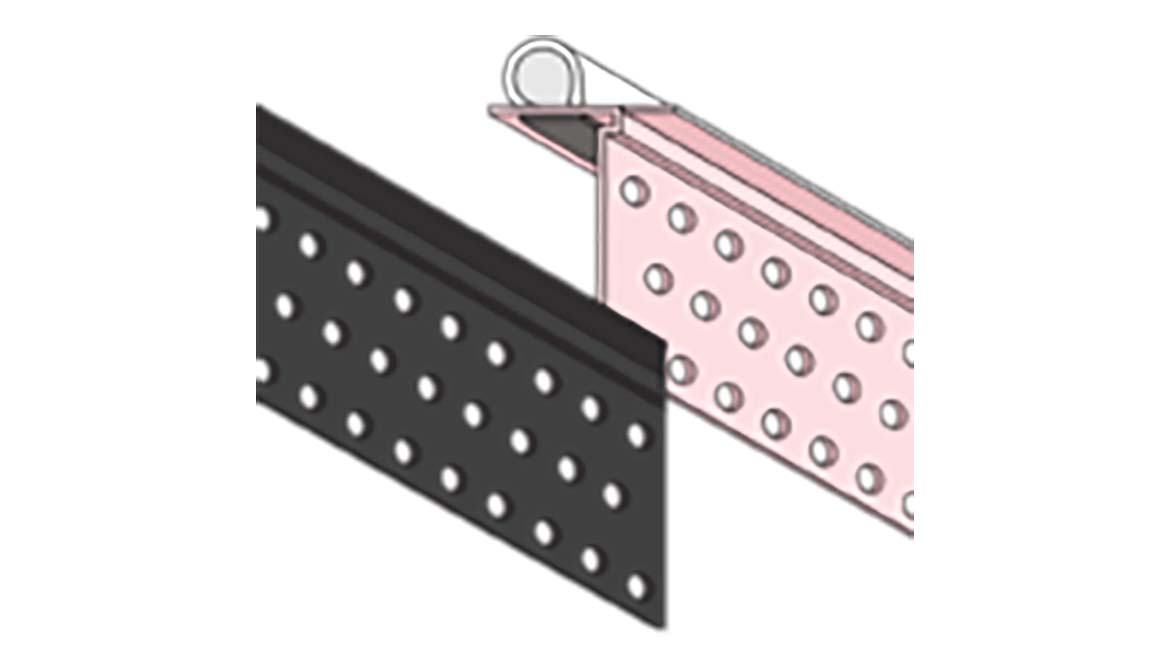

Deflection Bead

CEMCO

The company’s SUPER SEAL-X is a surface-mounted deflection bead tested to UL 2079 standards. It provides one- and two-hour firestop solutions in vertical joints for both standard wall and shaft wall types between dissimilar material applications. The product is tested over vertical window aluminum mullions in UL Assembly WW-D-0182, with up to 50 percent compression, and installs fully cured, unaffected by water, moisture or temperature. It is available in all black and pink vinyl with a white bubble gasket, perforated mud leg and intumescent strip that can be installed using spray adhesive and staples. The bead can also be painted for any exposed applications. The product remains flexible for the life of the assembly, provides a STC rating and can be used in top-of-wall, bottom-of-wall and vertical joints.

The company’s director of business development, Steve Farkas, says industry shows are the best opportunity to interact with many of its customers and end users.

“Rarely do we get to spend that level of quality time in front of the end user to also listen to their wants/needs in the field, giving us ideas and energy to push forward with innovations that save time, increase safety and promote profitability,” he says.

The marketing of CEMCO—from a corporate perspective—is such an important and demanding aspect of the job that he feels the need to be there from start to finish and see how customers respond to the company’s efforts.

Because of that, Farkas learned many things from attending this year’s show. “Bigger is better! The more attendees, the more opportunities we have to speak with and learn from those in the field using our products,” he says.

“[I also noticed] the general feeling that the economy is providing sustainable growth for the contractors in this country,” he says. Despite the turbulent times, the cautious optimism is great to see.

For more information, visit cemcosteel.com.

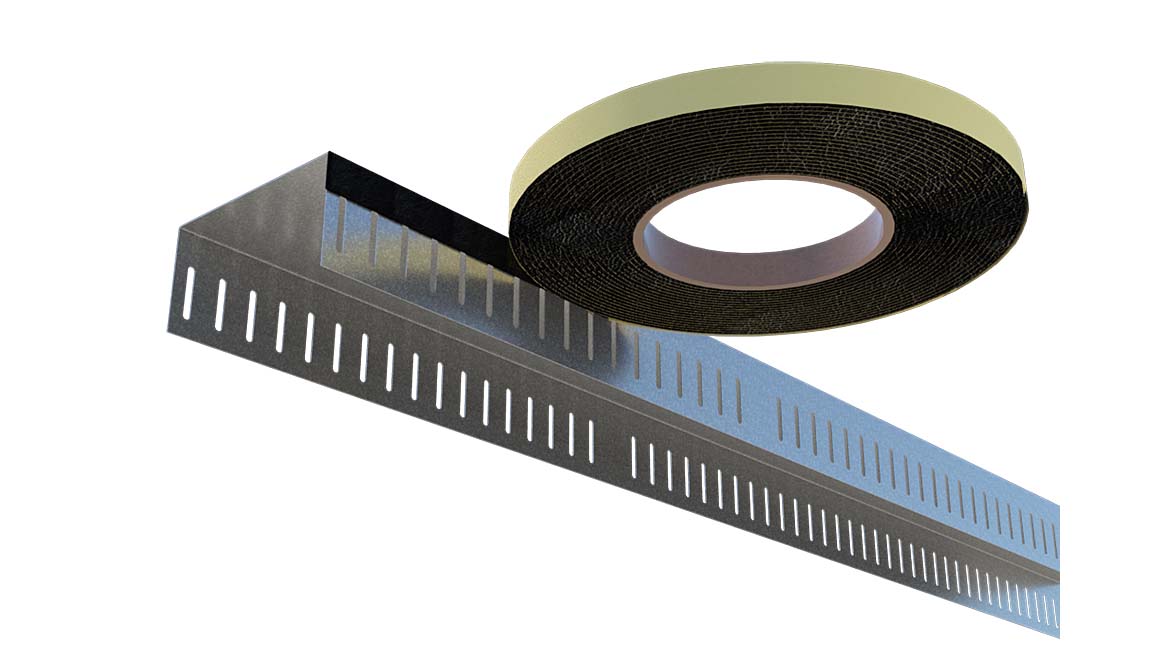

Firestopping Tape

ClarkDietrich

The cold-formed steel framing product manufacturer is giving framing contractors greater flexibility in leveraging the firestopping power of its BlazeFrame family of products with the introduction of BlazeFrame Tape.

Sold in rolls, the product is a 2-millimeter-thick strip of intumescent material that can be field-applied to metal framing profiles to provide an air and smoke seal. When exposed to heat above 375 degrees Fahrenheit, the intumescent material expands up to 35 times its size. This provides protection from heat and flame passage during a fire event.

When used in conjunction with the applicable deflection tracks and the company’s Perimeter L-Bead, the tape is UL 2079-fifth edition compliant with UL 2079 Class II or III Movement Capabilities.

“We’ve had great success with BlazeFrame firestopping products since launching in 2012. Now, we’re making it even easier for our customers to benefit from the added safety and labor savings of these technologies with BlazeFrame Tape,” says Ryan Reed, category manager at ClarkDietrich. “Field-applying BlazeFrame Tape gives contractors the ability to install a fire-rated joint before drywall is installed and delivers the same performance as our other BlazeFrame products.”

The tape is available in 3/4-, 1- and 1¼-inch widths and features a peel-and-stick adhesive backing for easy application. Ordered through the company’s Clip Express, contractors can expect to have the product on-site within 24 hours of their order.

To learn more, go to clarkdietrich.com/products/blazeframe-tape.

Hybrid Construction Adhesive

DAP Global

The HD Max Construction Adhesive is a hybrid formula with polyurethane strength that provides durability and powerful adhesion, even in extreme temperatures. Built for the toughest applications, it is the first hybrid construction adhesive on the market available in a 28-fluid-ounce cartridge, making it an excellent-value hybrid formula for pros looking to accomplish larger jobs.

“DAP formulated HD Max provides hard-working pros with a premium hybrid formula that is a workhorse adhesive for many projects, in many conditions,” says Matt Nolder, adhesives product manager at DAP. “The 28-fluid-ounce cartridge makes HD Max the perfect combination of value and performance, offering pros a hybrid solution for larger jobs.”

Featuring polyurethane strength, HD Max bonds virtually everything—even non-porous substrates, including drywall—with exceptional adhesion and durability in both indoor and outdoor environments. Whether working in scorching heat or freezing cold, the product has the ability to bond in extreme temperatures, as it can be gunned out and bond anywhere from zero to 120 degrees Fahrenheit. Its low-odor formula also makes it ideal for interior use.

It also has the ability to adhere to wet surfaces while being easy to gun and control. In addition, it delivers a solid and waterproof bond that’s reliable and flexible.

“DAP’s new HD Max alleviates project limitations pros face from typical hybrid construction adhesive cartridge sizing. HD Max’s 28-fluid-ounce cartridge allows them to tackle large projects and a wide variety of applications with just one hybrid product,” Nolder adds.

For more information, visit www.DAP.com.

Snap Studs

Flex-Ability Concepts

Bridging between studs is necessary when framing a wall to prevent twisting and buckling, and conventional methods come with a certain level of frustration. In response, the company’s Snap Lock, a new bridging bar, is an easier and faster way to snap studs into place.

The product is designed to be installed as the wall is being framed. In essence, the product accomplishes stud spacing. The bridging bar has a starter clip that can be used in the first stud of a run. A screw at the beginning and the end of a run are the only screws needed, no matter the length of the run. Other bridging products require clips and screws at every stud.

Snap Lock is available in 20- or 16-gauge steel and 16- or 24-inch lengths. If a different length is needed, maybe at the beginning or end of a run, the bridging bar flanges can be snipped. The product can then be folded over and screwed into place using the small pre-punched holes. Larger holes are also provided in Snap Lock to allow for other products, such as conduit, to easily pass through.

Snap Lock eliminates fishing CRC or longer bridging products through stud knockouts, which can be challenging to do while framers are hoisted high on a lift. It is strong enough to provide exceptional torsional stud restraint, even in load-bearing walls. While not necessary, the tab on the bar can be hammered into place for added strength.

“Snap Lock is a relatively simple product that eliminates the need to measure between every stud,” says Robert Widmer, director of sales and marketing at Flex-Ability Concepts. “With it, contractors have a simpler, faster and stronger way to provide bridging and to ‘snap’ studs into a layout.”

“I am always impressed with the professionalism and organization of our trade associations,” says Widmer, who added that the events the company attended included the Supplier Manufacturer committee meeting and the session on AI.

Visit flexabilityconcepts.com to visualize the simplicity of the install.

Optimized Fastener Pattern

National Gypsum Co.

The MaX 16 optimized fastener pattern is a 16-inch o.c. optimized fastener pattern for single layer, one-hour UL fire-rated assemblies on metal framing.

Applicators will no longer need to discern between non-rated single-layer partitions and most one-hour fire-rated steel stud assemblies with metal framing spaced 16 inches on center. The 16-inch-by-16-inch pattern is applicable for both horizontal and vertical applications.

The combination of the pattern with the company’s patented GridMarX installation guide marks will make installation simple and save time and money. A recent time/motion study conducted by RSMeans data from Gordian, identified that when compared to the industry standard, the pattern will save up to 46 percent in installation time and as much as 24 screws per 4-foot-by-12-foot board when applied in a vertical orientation.

“Using MaX 16 with GridMarX will result in significant savings in installation time, labor cost and material cost,” said Matt Gallagher, gypsum systems product manager for National Gypsum. “The implications for increased fastener accuracy, enhanced installation quality and easier assurance of compliance are enormous—helping both the contractor and code official.”

GridMarX installation guide marks are printed on the surface of all 4-foot-wide gypsum board products manufactured by Gold Bond Building Products. Guide marks run along the board lengthwise every 4 inches along both edges, at 16 inches from each edge and down the center 24 inches from each edge, to help quickly identify fastener lines for studs and joist framing. Cuts can be made without having to draw lines.

“Labor and materials are among the most significant construction costs,” says Jay Watt, director of marketing for National Gypsum. “We are continually seeking innovative ways to help our partners increase productivity and efficiency on the job site.”

The company’s MaX Calculator provides an opportunity to determine the savings of using MaX 16 or MaX 12. The user can simply enter their labor and fastener costs, square footage of the job and labor type to calculate the potential amount of labor and materials saved on their next project.

For more information, visit nationalgypsum.com.

Fire-coded Panels

USG Corporation

The company’s Sheetrock EcoSmart Panels Firecode 30 (UL Type FC30) are lightweight, 5/8-inch gypsum panels that have been formulated to achieve all of the same strength and physical performance characteristics as standard panels at a lower environmental impact and reduced weight. The panels feature a non-combustible gypsum core that is encased in 100-percent recycled face and back papers, which form a high strength-to-weight ratio composite design.

The face paper is folded around the long edges to reinforce and protect the core, and the ends are cut square and even. The long edges of panels are tapered, allowing joints to be reinforced and concealed with joint treatment systems. The panels are UL Classified for fire resistance and can be used in any UL Design in which Type FC30 panels are listed.

Sustainable and ultra-lightweight 5/8-inch panels for interior wall and ceiling applications:

Meet Architecture 2030 Challenge for Products

Up to 25 percent less global warming potential

Up to 30 percent less weight reduces transportation fuel energy by up to 20 percent

Living Building Challenge Red List Free

Contain 100 percent USDA-certified bio-based content

Have up to 97.3 percent recycled content (regionally available)

Achieved GreenGuard Gold Certification and qualify as a low-VOC-emitting material (meet CA 01350)

Certified in USGBC LEED v4—may assist in achieving additional credits

Received Underwriters Laboratories Inc. classification for fire resistance (30-minute and one-hour fire-rated walls), surface-burning characteristics and non-combustibility

Comply with ASTM C1396 (Standard Specification for Gypsum Board) for 5/8-inch and non-Type X gypsum wallboard

Offer comparable strength and sag resistance to standard 5/8-inch Type X

Chris Griffin spoke at this year’s opening keynote session at the 2024 AWCI conference.

“In today’s rapidly evolving world, individuals at all levels within organizations face a multitude of complex challenges, including adapting to technological advancements, managing remote work environments, economic uncertainties and addressing the growing concerns of social division,” Griffin says. “Amidst these challenges, one crucial element stands out as an indispensable need: human connection.”

“Our business is affected by factors outside of our control—and outside of our industry,” he says. “First, we’re looking at the federal decisions around interest rates, and what this will mean for timing, cadence and magnitude of interest-rate cuts.

“Second, we have inflation to contend with. And third, the fact that this is an election year promotes further uncertainty about construction outlooks and the economy as a whole,” Griffin says, adding that the effects of these factors remain to be seen and could hugely influence our industry.

Griffin says the industry is nowhere near being on life-support—but there are the usual suspects of challenges ahead: recruiting and retaining talent, economic uncertainty and any number of world events that could lead to instability.

“The latest forecasts call for housing starts in the range of 1.30-1.40, with single-family start-ups up around three percent,” he says. “While there isn’t a predicted rebound from COVID in new, non-residential builds, it looks like the commercial market is remaining steady without further material declines in the short-term.”

Griffin continues to say the construction sector is predicted to have the largest increase in employment of any sector, adding nearly 800,000 jobs through 2024 (according to the U.S. Bureau of Labor).

For more information, visit usg.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!