Contractor of 2024: Curtis Partition

Manhattan’s Curtis Partition is one of New York’s largest wall and ceiling contractors. They have also been named W&C’s Contractor of the Year.

Walls & Ceilings magazine has selected its Contractor of 2024, Curtis Partition.

Walls & Ceilings magazine has selected its Contractor of 2024, Curtis Partition.

The winner was chosen by a panel consisting of W&C’s publisher, editorial staff and editorial advisory board. The goal of the award is to honor a contractor that employs the best industry practices, provides a good working atmosphere for employees and excels at both quality workmanship and customer service.

“Curtis Partition is an excellent New York outfit—the company operates a tight ship with many services to its name. Its investment in its staff and technology posits them as a major force in the New York market and beyond,” says W&C Associate Editor Michael Levitt. “We’re excited to name the company Contractor of 2024.”

The magazine congratulates Curtis Partition for this award. We believe the company is as progressive and quality-minded as any.

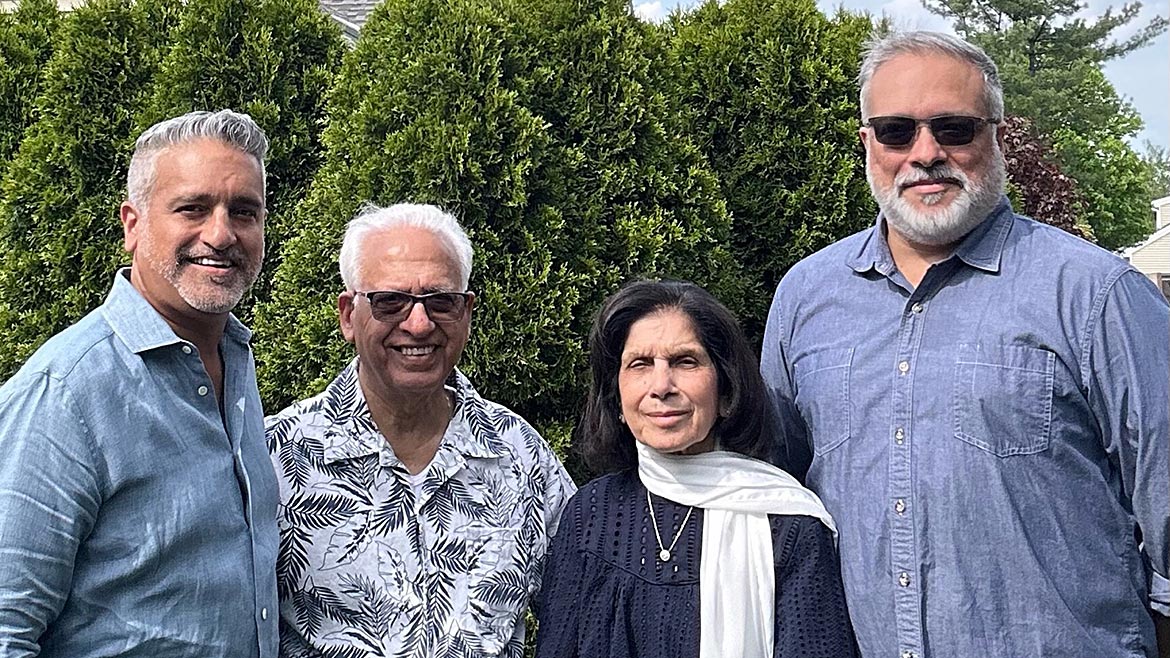

In 1969, amidst an unstable India, Sudarshan Narula emigrated to the U.S. with a background in architecture and only a few hundred dollars. He began his career as a draftsman with Curtis Partition in New York, earning just $4 an hour. Soon after, he and his wife, Bimla Narula, started a family and welcomed their two sons, Ankush and Ajay.

Over the years, Sudarshan Narula climbed the ranks and ultimately became the president of the company in 1993. By 1997, he had acquired the majority share of Curtis Partition, which has since executed over $700 million worth of work, completed more than 5,000 projects, and built in excess of 25 million square feet, establishing itself as a leading drywall and ceiling contractor in the New York metropolitan area.

In 2002, after several years in Silicon Valley, Ajay Narula joined his father at Curtis Partition, following in his father's footsteps. He eventually earned his current titles of CEO and President in 2012.

Curtis Partition Corp. is, in its own words, always evolving. From the time the company opened its doors in 1959, the industry has seen massive shifts in project scale. Yet for all the changes, many drywall and carpentry contractors still do things the old way.

As a wall and ceiling contractor, Curtis Partition embraces technology to deliver large-scale work with boutique quality. Its team’s backgrounds in architecture, tech and construction management helps it deliver a product other firms can’t.

The trade contractor, arguably one of New York’s largest, services and installs drywall, ceilings, rough carpentry, finishing, millwork and various elements of Division 10, as well as acoustical plaster, painting, flooring and a few other architectural trades.

Top Manufacturers & Distributors

Armstrong Ceilings

CertainTeed

ClarkDietrich

USG

Colony Hardware

FBM

L&W Supply

Park Ave

Tanner Bolt

This year, the company celebrates its 65th anniversary.

“I got involved with the construction industry as my father was the president and majority owner of Curtis Partition,” says President/CEO Ajay Narula. “I had been working in the tech industry back in 2001 in Silicon Valley. It was very apparent that the .com bubble was indeed bursting, and I had no interest in ever working for someone else again. We were a well-capitalized company that had an unnecessarily large burn rate, not dissimilar from many companies in the Valley at that time.

“I decided I wanted to run my own business and be the ruler of my own fate, so I made a deal with my father to join Curtis Partition, but only after I traveled for the next eight to nine months,” Narula adds. “So that’s what I did.”

Current Success

The company employs anywhere from 170 to 300 people.

“When I started in the business in 2012, our revenue was probably closer to $10 million and our total staff was less than 40 to 50 people, both in the office and on the job sites,” Narula says. “Today, our revenue is between $70 and $100 million. And our internal staff is around 30 people and our project site staff fluctuates between 140 to 270 people.”

Narula says that business has been consistent and the company is doing fairly well. Curtis Partition is fortunate to have a great group of customer-partners who align well with the company and its core values of integrity, innovation and partnership. They understand that the trade contractor is not going to rest on the laurels of the past and that it truly wants to see the advancement of the industry. He adds that the customers also understand that, in order for them to create the highest value proposition for their clients, they need partners like Curtis Partition to raise the bar and challenge the status quo.

Pandemic Changes

Side Businesses

The company has also set up three other companies to diversify its offerings to the construction industry. All of these businesses’ formations were driven by the significant needs that Curtis Partition had, combined with the gaps in the marketplace to service those needs.

Juniper Construction Services is an outsourced services company serving the construction industry with services like quantity takeoffs, virtual project management, back office accounting and virtual administrative support, and business intelligence services.

Engineta is a tech services company that focuses on 3-D scanning, 3-D modeling, process documentation, progress tracking, kitting and software engineering.

Offsite Construction Solutions is a manufacturing company that focuses on prefabrication, panelization and kitting.

In Narula’s opinion, New York City has maintained itself as a relatively busy market. However, the type of work that it sees more and more has changed over the last five years since COVID.

“Prior to the pandemic, we were seeing significant amounts of commercial fit-out work and new commercial construction,” Narula says. “New commercial construction and commercial fit-out (renovation work) are the two sectors that have become very hard to come by and are therefore quite competitive.”

It seems that the two areas of significant growth in the New York City market are health care/laboratory and airport/transportation.

Curtis Partition has been fortunate to have deep experience in both of these sectors and, therefore, has been able to acquire a fair amount of both types of work.

Interests and Challenges

What is the most interesting aspect of the job for Narula?

Narula says that an amazing part of the job is working with people that have a completely different life experience, both personally and professionally.

“When I’m working with some of our foremen and field managers/supers and I’m being taught how to think about technical construction challenges, it reminds me that I learned almost everything I know about construction from the men and women who wear a toolbelt,” Narula says. “I am so lucky to get this education that one could only have by being in a position like mine.

“I think the other exceptionally interesting part of the job for me is finding new synergies and opportunities by infusing legacy processes with innovative and progressive, often technology-driven, approaches,” Narula adds.

He says that the perspective at Curtis Partition is, “If we are not looking to advance the industry forward and looking for mutual wins with our clients, we are not going to find sustained success and we are definitely not living up to our core values.”

On the other side for Narula, what he finds as the most difficult aspects are:

- His first issue is when the top brass sees someone get hurt. Sometimes, the team feels that they were avoidable incidents. He says the company has worked very hard to create a strong safety culture and a true focus on the health and well-being of its workers. To best represent that, Curtis Partition changed its tagline this past year to “being human first.”

- The second aspect that Narula finds challenging: it’s related to its collective bargaining and project labor agreements. “At the end of the day, the carpentry union and the signatory contractors are major stakeholders in each other’s businesses so finding the alignment is not just something we want; it’s something we all need. Innovation and technology could be the great equalizer with the nonunion, a true free market system."The history of the relationship between the union and signatory contractors was that of mistrust and misalignment, particularly when it came to the implementation of technology and innovation, but things seem different today," Narula says."I truly believe we have come a long way from where we were, but we still have great strides to make if we want to get to the point of true alignment and neither of us can do it without the other. I’m optimistic that we will find that alignment in the coming years.” he says. “As mentioned, we all know this is not a ‘nice-to-have’. This has now become an existential issue for the unions and the signatory contractors so failure is not an option.”

Company Outlook

The company’s backlog is fairly strong right now, and the company is seeing some unique opportunities in which it wants to take a more prominent role.

“We really believe in the ‘design-assist’ project approach, so we would like there to be greater consideration for the drywall trade when those structures are being set up by owners and construction managers. Often, there’s not great consideration for our trade and we end up being precluded from these conversations,” Narula says. “I firmly believe that there is immense value in working with our trade on any design endeavor, merely given the fact that we integrate with almost every other trade on the project. We are often considered the pacesetters of the project due to this dependency that so many have on us, so it’s baffling to me how this is not a standard.”

“Unlike many others who do what we do, we have enabled ourselves with a deep knowledge of 3-D modeling, and this proficiency enables us to participate in any design-assist projects,” Narula adds. “This, combined with our proficiency in prefabrication and manufacturing and the workflows we have created to facilitate and optimize the manufacturing process, should provide a tremendous value to the CMs/GCs and owners on design-assist projects.”

Overcoming Difficulty

Narula loves challenging projects. He and the company enjoy complexity and designs that require the company to really think and ensure that it has looked at something 100 ways before it comes up with an approach. He says that the members of Curtis Partition not only love showing their capabilities on these challenging projects but they also love being given an opportunity to truly enhance the project experience for all stakeholders.

Beyond that, what also sets the company apart is its ethics and attitude. We believe in checks and balances and the ideas around true corporate governance. We are excited by the industry moving towards greater accountability as we believe this is a key differentiator for us. Our industry, particularly in the New York market, has a history of corruption and unethical practices and I believe we are at a point where there is much more proactive risk mitigation by the CMs, GCs, and owners.

“We don’t know if we’re one of the best contractors in North America, but we know we continue to strive towards that distinction,” says Narula. “It might sound like false humility, but at Curtis, we do not believe in entitlement. We believe we have to earn our place at the table every day. We go out of our way to not repeat mistakes and to ensure we are putting our all into every project. Our operational excellence is so important, and I truly believe that is one of the reasons why 100 percent of our customers have asked us to bid on more projects after we’ve worked together.

“My father is a remarkable person who instilled our values into the people he worked with,” Narula adds. “I would say these achievements of creating an identity of ethics and integrity is something that he did with sincerity and it was well before I ever came along, but by doing that and living it every day, it has become so deeply rooted in who we are as a company.”

“We sincerely appreciate acknowledgments like this one, but this is not an achievement; this is truly an acknowledgment,” Director of Risk Management Eve Biggers says. “The only true achievement that I can speak of that I feel carries significance and follows the form of our values is in the realm of safety. 2024 is shaping up to be one of our safest years yet. Our incident frequency is down, lost time has decreased significantly, and severe incidents have been nearly nonexistent. Reflecting on this year’s safety achievements, we have much to celebrate.

“This year marks a strong comeback for our team, demonstrating our resilience and sharpened focus on safety,” Biggers adds. “The challenges of previous years remain top-of-mind, reminding us of our renewed commitment to a safe work environment. Our team’s dedication to safety is clearer than ever, even as we tackle increasingly intricate and unique projects. Each new challenge reinforces our belief that safety is at the heart of our success.”

Project Profile

Location: Chase Sapphire Lounge at LaGuardia Airport

Architect: Corgan

Construction Manager: Turner Construction Co.

Wall and Ceiling Contractor: Curtis Partition

Curtis Partition’s scope was all wall partitions and ceiling systems, including plaster finishes. The company also provided GFRG “tree” column enclosures.

The Chase Sapphire Lounge at LaGuardia Airport represents the ultimate in traveler relaxation and rejuvenation. The lounge’s design made maximum use of low-height slabs, removing an extensive section of the upper-level slab to create two-story volumes and enhance the sense of openness in a space without windows. Soffits and light coves were created in several amoeba-like shapes around the space. High-end finishes of stone, metal and millwork add to the warm and inviting feel of the space. Tree-like GFRG column enclosures and the use of plaster and stretch-film ceilings provide an opulent environment. The lounge features a circular bar, game room, wellness suite, family lounge, quiet areas, private suites, a full-service kitchen and more.

The member-contractor provided all walls, ceilings and GFRG columns. In addition, door frames and hardware, and several specialty scopes were provided. Ceiling systems included Level 5 drywall, baffles and extensive plaster work, all matching the curved outlines of the soffits and coves. The soffits were laid out using a laser-projection layout system, which significantly reduced layout time for the compound curves. Stretch-film ceilings with a mirror finish were provided at GFRG column enclosures.

The column enclosures were irregularly shaped tree trunks with a vacuum-laminated woodgrain finish. The spectacular space has been featured in many national prime-time commercials and is the pinnacle of lounge space in the new world-class LaGuardia Airport.

The member-contractor worked closely with the construction manager and design team to address several complicated geometries and work within existing conditions. This successful project has directly led to engagement of the member-contractor’s team by the construction manager’s team for another high-end project.

Products Used:

Armstrong – GFRG and drywall framing products

USG – ceiling systems

ClarkDietrich – cold-formed metal framing

Hilti – firestopping/fireproofing products and fasteners

National Gypsum – gypsum board

Henry Products

Offsite Construction Solutions – prefabricated drywall and framing shapes

**Led by Ajay Narula (CEO), Gary Bashur (CFO), and Steve Jureller (COO)…

***Other key management includes

- Mike Carnavale, Vice President Of Estimating and Construction

- Edwin Leong, Vice President of Compliance

- Neha Desai, Vice President of Human Resources

- Arianna Etwaroo, Director of Administration and Executive Assistant

- Eve Biggers, Director of Risk Management

- Cathal Whyte, General Superintendent

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!